Then click the Solve button in the window that pops up, followed by the Okbutton in the Solver Results pop-up. To solve the raw mix, click on the Data tab at the top of the excel screen and choose Solver (in the Analysis group). Then enter whatever raw meal targets you want for LSF, SR and AR in column G, lines 15,16 & 17. To use the spreadsheet change the names and chemical analyses of the raw materials to whatever you want.

Download Combined Footing Design Spreadsheet. Download Design Of Reinforced Concrete Staircase Spreadsheet.

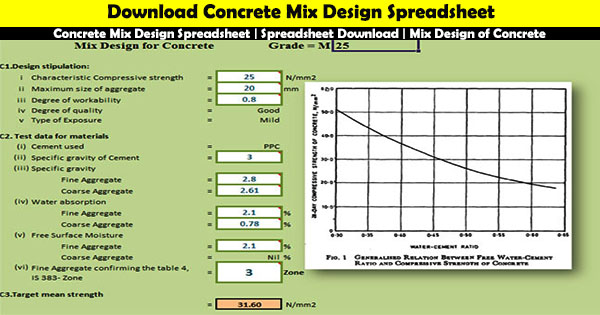

The purpose of concrete mix design method is to make proportion of the materials of concrete (cement, sand, and aggregate) inexpensively to attain superior strength and stability on the basis of the materials obtainable at a construction site. Work out the weight of materials essential for making the calculated volume of concrete.

In terms of concrete planning it is a huge help as any special requests can be. For concrete mix design, we have to perform many laboratory testing and calculations to find right mix proportions. Measure the volume of concrete necessary for slabs, walls, footings and columns.ĥ. Concrete mix design is the process of detrmining right proportions of cement, sand and aggregates for concrete to achieve target strength of concrete.

There is option to settle your own size and rate of premix bags.Ĥ. Measure the number of premix bags necessary for your project.ģ. Measure cement, sand and aggregate quantity in concrete.Ģ. Concrete Calculator is a free calculator that can be used for the following purposes :-ġ.

0 kommentar(er)

0 kommentar(er)